There really is an xkcd for everything.

xkcd

A community for a webcomic of romance, sarcasm, math, and language.

As if they did not have enough issues with their backwater imperial units...

Interestingly enough, this concept was used in pattern making for casting machine parts back before modern machining and parts manufacturing.

They were colloquially called shrink rulers, and looked like a standard ruler, but were actually longer to account for the shrinkage of the material being cast.

For example, say you're casting a part from iron, which shrinks 1% as it cools, which amounts to 1/8 inch per foot.

An iron shrink rule would look standard, but actually measure a foot as 1 foot 1/8 inches to account for the shrinkage (this is an example and not meant to be actually accurate).

Source: am historian that interviewed pattern makers that used shrink rulers in their work.

Edit: spelling

It shrinks? Like a frightened turtle!

That’s what happens when things cool down… It is the cold, that why it looks small 😳

I need to get a shrink tape ruler like this. I own a skoolie (used school bus converted to a motorhome) which is 35' 4" long from bumper-to-bumper. A lot of campsites have rules where RVs can't be longer than 35'. My thought was to get a tape measure with feet just slightly longer than normal and use it to make my bus appear to be shorter than 35'.

At one time a 2 x 4 really was 2" x 4". Very old houses will have these in the walls, not planed and quite rough and splintery. I think I still have splinters from the 1913 bungalow I renovated more than 30 years ago.

I've worked on a lot of pre-1900 houses (I even grew up in one) and the 2x4s from back then really were 2" x 4" instead of the modern 1.5" x 3.5". Two years ago I bought a house built in 1942 and I demolished one interior wall and re-used the studs from it to build some new walls. I kept building these walls 1/2" too tall even though I measured and re-measured the spaces I was putting them into very carefully. I eventually realized that these 1942 studs were not in fact 1.5" x 3.5" like I had been assuming, but were actually 1.75" x 3.75" (the extra 1/4" in width of the top and bottom plates of my walls is where the phantom extra 1/2" was coming from). So apparently there was a transitional period between the real 2" x 4" 2x4s and the 1.5" x 3.5" ones.

I discovered another weird transitional thing in this house. The old houses I worked on all had lath-and-plaster walls, with strips of rough wood lath covered with a thick rough plaster layer which was in turn covered with a thin smooth plaster layer. Modern houses of course use sheetrock, but my 1942 house covered the bare studs with 16" x 16" pre-formed interlocking blocks of 1" thick rough plaster, and then smooth plaster was laid over these blocks. I first encountered these when tearing down the ceiling in my kitchen, and these things were unbelievably fucking heavy. They basically weighed as much as solid stone of these dimensions, and I can't imagine what it must have been like to install them initially. It surely must have been a two-man job.

Edit: another fun experience I had was renovating an Atlanta house that had been built in 1843. When we tore down the original lath-and-plaster walls, we found embedded in every single wall and ceiling a single dead, flattened rat. That house must have stunk to high fucking hell when they first moved into it. I like to imagine that it had been built with slave labor and this was some well-deserved payback.

Interesting. We found some 3/8" drywall in the 1913 house, dating from some renovations that appeared to have been done in the 1950s or 60s. We also found a mummified sandwich.

Just when I thought I managed to contain my metric arrogance...

It's from a time when you bought undried and planned wood rather than dried and planned like we typically do now.

It's less a quirk of the imperial system and more a quirk of the lumber retail system, which is older than the metric system.

The biggest difference is that in places that use dimensional lumber and the metric system the pattern is to sell by actual dimension, rather than nominal. So a wall stud might be 45mmX145mm, or 63mmX75mm for a rafter, depending on your country.

Most north American hardware stores also sell by finished sizes now.

harrumph..

Those nonsensical rules exercise the brain more. Helps stave off mental deterioration.

Carpenters in the USA have a higher mental acuity at advanced ages than scientists

Maybe they just measure their age wrong.

I don’t think so, they are all 6 doggers old or more

ITT: people arguing about how to measure their wood

A tale as old as manhood

Its 2x4 before drying and planing.

The tree was 2x4, I've no idea what they've done with it.

Maybe I’m being daft (I probably am).

After wood is planed and dried, I thought it would have gotten smaller.

In the image, 9CM lumber measurement is smaller than 9CM metric. Meaning when 9CM lumber shrinks it’ll be even smaller than the 9CM metric.

Have I got this backwards?

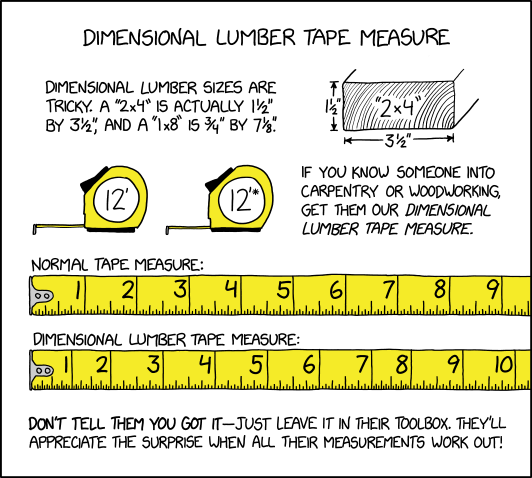

The joke is when you purchase a 2x4, it measures 1.5x3.5 and not the advertised 2x4.

lol, learn something new every day!

Huh, the explain link says the dimensional sizes originated from the wood being cut at the listed size while green, then shrinking as it dried. I was told that it was done for construction purposes, where the wood would likely be covered by plywood or drywall that would bring the dimension up to size. I never questioned it before; that always seemed plausible enough.

Wood does shrink while it dries, and that is the reason why a "2x4" is actually 1.5x3.5, but you're missing a lot of detail in there.

To make a tree into boards, first a lumberjack fells the tree and bucks off the branches. It is then taken to a sawmill where a big clumsy saw slices it into kind of rectangular shapes. I will gloss over some nuance here about the algorithm chosen to do that and how it relates to the growth rings to produce boards of different qualities. You now have green boards, VERY wet. If you were to build something from these boards, as they dried they would warp and twist and pull the assembly apart. So it has to be dried.

At commercial scale, this is done by stacking the boards with spacers in between so air can circulate through the pile and letting it sit outside for a few months, and then the piles are taken into a kiln and heated for a couple weeks. The weight of the stack, or perhaps straps holding the stack together, has kept the boards relatively straight, but they will have warped a little. Before they're used for much, they have to be more precisely cut so they are straight, square and true.

Woodworkers making fine furniture tend to buy their lumber rough cut and mill it themselves, so that the lumber is as flat, straight and square as possible. Let all warping happen while the board is rough and mill it as a first step in building so that the pieces are very precise, and then the finished assembly holds itself true. Woodworkers buy wood per unit volume; it's usually priced per board foot. A board foot is 1 foot long, 1 foot wide and 1 inch thick, or 144 cubic inches. A 1 inch thick, 6 inch wide, 8 foot long board is 4 board feet. Checking out at the lumber yard requires a bit of middle school geometry homework.

Carpenters building houses or sheds used to do the same. In the early 20th century, lumber companies shipping lumber long distances by rail started shipping wood pre-milled. It doesn't really matter if the boards are a little warped; the worst boards in a stack can be cut into the smaller pieces you need, the better ones used whole for studs or plates. Pre-milling the boards at the sawmill means that it's cheaper and more efficient to ship the lumber, the sawmill now has the sawdust/shavings/chips to make particle board, OSB and other engineered lumber products out of, and the carpenter gets a commodity product he can buy and use rather than a raw material that needs further processing. Because they're all the same size, they're sold at a price each. It was a true 2 inches by 4 inches in the kiln, and the milling has been done for you.

Before they're used for much, they have to be more precisely cut so they are straight, square and true.

One trip to home depot determined that was a lie.

There is, now, a separate problem where 2x4s specifically are made of very inferior lumber. most will have either pith or wane, and I've seen them have both, which means the tree they harvested is maybe 5 inches in diameter and they might have gotten 3 2x4s out of one log. Even compared to when I was in carpentry class in high school the quality of construction lumber has decreased. Larger boards like 2x8s or 2x12s don't similarly suffer because it's impossible to make them out of saplings. But still.

None of the above is true, or at least isn't the full answer for why today a "2x4" is missing an entire half an inch all the way around. The shrinkage due to drying is around 5% (and the real math there is more complicated, as wood shrinks different amounts in different directions relative to the grain), which would only account for 1/10" of difference in the thickness of a 2x4. With some species of pine it's as low as 2%.

No, the lumber industry has consistently shaved boards in order to fit more into rail cars for transport and make more money and spend less per plank on transportation costs. Various lumber consortiums determined via internal testing that the smaller board sizes are still "sufficient" for their intended purpose vis-a-vis structural integrity of stick framed residential buildings.

Of course the answer is "capitalism". It always is.

that's one of the common excuses that the mills quote. It's bullshit of course, but it sounds plausible so they continue to get away with it.

Another bullshit excuse is that they're providing an additional service by milling and planing the lumber for you, and that the nominal measurement is before that process.

It's all just greed. If they could get away with selling a 2x4 that was half an inch thick, they would. At least it's all standardized now.

I don't think this is true. There was a transitional period around the 1940s where 2x4s were 1.75" x 3.75", and that wasn't because wood shrunk half as much as it does today.

This hurts so bad to think about

Which part? The ruler that can't exist or the part where finished lumber is smaller than the listed size?

The thought of reaching into my toolbox and pulling out a measuring tape that's labeled wrong without knowing it. He did a good job with this comic. That thought sucks so bad.

My sawyer showed me a measuring tape graduated in tenths of a foot. Someone manufactured that for some reason.

This is how you become a character in House of Leaves.

You don't even need a custom one. Readily available is the universal tape measure where the relationship is marked as 2.54 units, equals 1 inch.

It means that a 2 x 4 is actually 5.08 x 10.16, which leaves you with a margin for surfacing and sanding.

american lumber doesn't use standard imperial units. an "inch" isn't the standard you'd expect on a so-called "nominally" 2 inch by 4 inch board. just attempting to use metric without accounting for the extra wackiness added by lumber 'measurement' on top of standard imperial silliness, you'd end up with a bunch of errors.

tl;dr: a 2" x 4" board actually measures something like 3.81cm x 7.62cm.

I understand.

I was making a joke about secretly introducing a metric tape measure.

I realise that my sense of humour is not universal, like the use of SAE .. or Fahrenheit 😇

That will go nicely with a tape measure that uses the Chinese inch (cùn), which is equal to 1.312 imperial inches

I had a client who wound up with one of those not realizing what it was, which caused him no end of problems until I ultimately figured it out confiscated it from him. He got a regular US inch one in exchange. I had to look it up at the time, too, because the notion of there being a Chinese knockoff inch that's subtly inaccurate is one of those things that just seems so ridiculous on its face that it simply can't be true, right? Except it totally is.

I feel this was the true decline of America.