this post was submitted on 06 Sep 2025

482 points (98.2% liked)

xkcd

12928 readers

130 users here now

A community for a webcomic of romance, sarcasm, math, and language.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

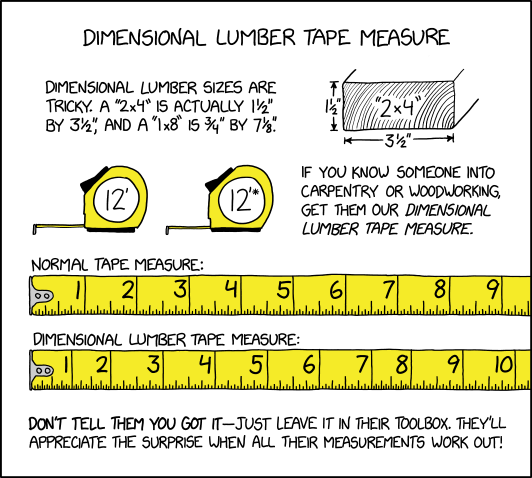

Wood does shrink while it dries, and that is the reason why a "2x4" is actually 1.5x3.5, but you're missing a lot of detail in there.

To make a tree into boards, first a lumberjack fells the tree and bucks off the branches. It is then taken to a sawmill where a big clumsy saw slices it into kind of rectangular shapes. I will gloss over some nuance here about the algorithm chosen to do that and how it relates to the growth rings to produce boards of different qualities. You now have green boards, VERY wet. If you were to build something from these boards, as they dried they would warp and twist and pull the assembly apart. So it has to be dried.

At commercial scale, this is done by stacking the boards with spacers in between so air can circulate through the pile and letting it sit outside for a few months, and then the piles are taken into a kiln and heated for a couple weeks. The weight of the stack, or perhaps straps holding the stack together, has kept the boards relatively straight, but they will have warped a little. Before they're used for much, they have to be more precisely cut so they are straight, square and true.

Woodworkers making fine furniture tend to buy their lumber rough cut and mill it themselves, so that the lumber is as flat, straight and square as possible. Let all warping happen while the board is rough and mill it as a first step in building so that the pieces are very precise, and then the finished assembly holds itself true. Woodworkers buy wood per unit volume; it's usually priced per board foot. A board foot is 1 foot long, 1 foot wide and 1 inch thick, or 144 cubic inches. A 1 inch thick, 6 inch wide, 8 foot long board is 4 board feet. Checking out at the lumber yard requires a bit of middle school geometry homework.

Carpenters building houses or sheds used to do the same. In the early 20th century, lumber companies shipping lumber long distances by rail started shipping wood pre-milled. It doesn't really matter if the boards are a little warped; the worst boards in a stack can be cut into the smaller pieces you need, the better ones used whole for studs or plates. Pre-milling the boards at the sawmill means that it's cheaper and more efficient to ship the lumber, the sawmill now has the sawdust/shavings/chips to make particle board, OSB and other engineered lumber products out of, and the carpenter gets a commodity product he can buy and use rather than a raw material that needs further processing. Because they're all the same size, they're sold at a price each. It was a true 2 inches by 4 inches in the kiln, and the milling has been done for you.

One trip to home depot determined that was a lie.

There is, now, a separate problem where 2x4s specifically are made of very inferior lumber. most will have either pith or wane, and I've seen them have both, which means the tree they harvested is maybe 5 inches in diameter and they might have gotten 3 2x4s out of one log. Even compared to when I was in carpentry class in high school the quality of construction lumber has decreased. Larger boards like 2x8s or 2x12s don't similarly suffer because it's impossible to make them out of saplings. But still.

I own a house built in 1942 and it's insane how good-quality the 2x4s are -- perfectly straight and true and no knots on them anywhere. They're so good that I've reused them for railings on my stairs. And this house was built as very cheap temporary worker housing during the war! I find it hilarious how much better the construction quality is on my house than on these million-dollar cardboard mcmansions they're building these days.