3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

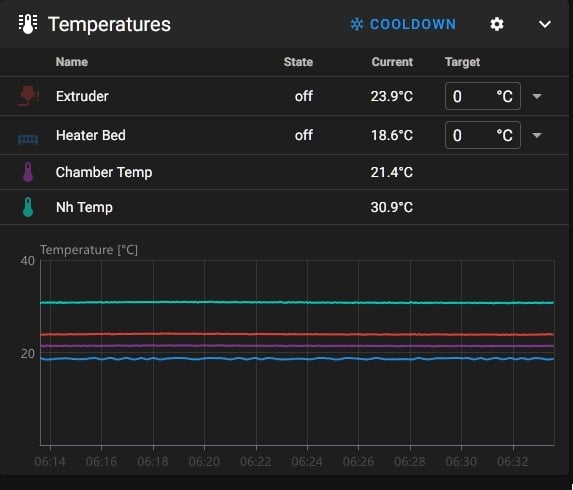

My voron with can toolhead, using a pt1000, I'd accept +/- a degree or so but that's a bit more than that. Could trying calibrating the pullup value manually? I'm using Generic 3950 for the sensor types on the Semitec 100k thermistors (chamber temp and plate temp are both using one of those), had the best results with that personally, could see if that helps things.

Agree that this seems like a bigger than desired difference.

Thanks for the point of reference. I am going to be doing some measuring and math tonight to try to figure out where the source of error is and how much it might/not matter when hot.

Before nitehawk I was using the same hot end and I copied the thermistor type from my prior config while setting up. The bed and extruder were much closer to each other when cold then.